Thermal Ice Storage Chiller Plant Installation - Manhattan, NY

Client: Confidential Financial Client

Summary: SIGMA7’s Chiller Optimization Study resulted in the replacement of outdated end-of-life centrifugal chillers with an Ice Chiller Plant, reflecting both SIGMA7's and their Client's commitment to improved energy efficiency and system reliability.

SIGMA7's integrated architectural and engineering team developed, designed and delivered a new cost efficient and electrical demand reducing Thermal Ice Storage Chiller Plant for our Client's NYC headquarters. SIGMA7 evaluated the existing facility loads, equipment, and infrastructure and determined that the existing chilled water plant consisted of three (3) aging 1,370-Ton Centravac chillers were quickly approaching end of service life and that replacement was timely and appropriate.

SIGMA7 reviewed the balance of the existing infrastructure and determined that the system would benefit from the installation of two (2) 1,300 Ton high efficiency chillers with variable speed drives and the addition and supplementation of a 1,000 Ton ice-duty chiller with variable speed drives and 8,400 Ton-hours of thermal (ice) storage, rather than replacement of the chiller plant in like-kind.

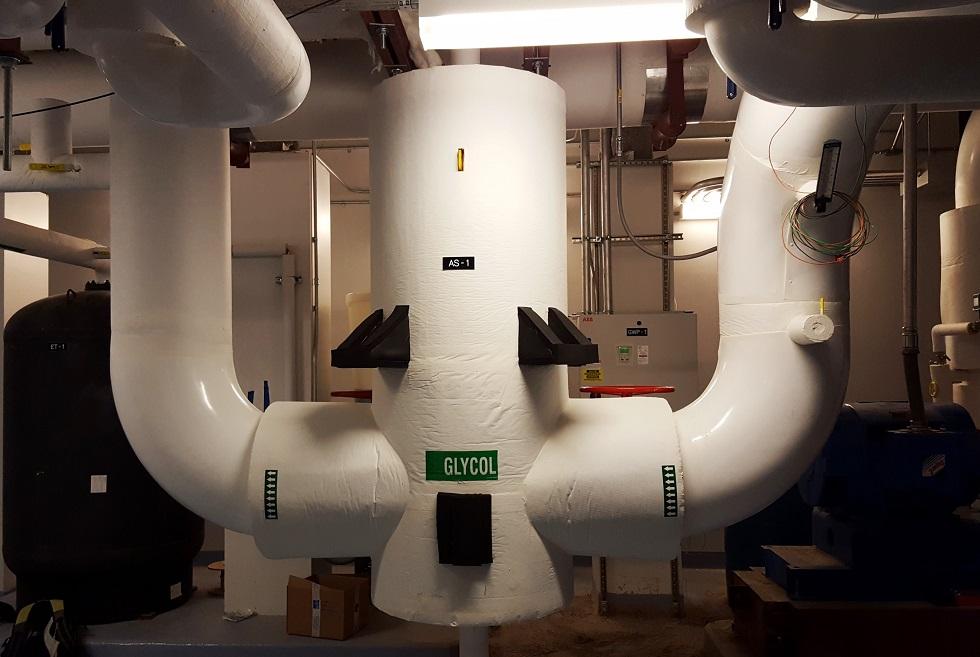

The proposed ice storage system would be able to contribute to meeting the cooling load and achieve peak demand load reduction. Additional modifications and enhancements were implemented to improve efficiency including the installation of variable speed drives on the primary chilled water pumps and glycol circulation pumps as well as BMS system optimization.

The project was registered with Con Edison / NYSERDA resulting in a significant incentive to the Client and has realized the reduction of their utility consumption and demand charges. The peak demand charges alone were reduced by nearly $1MM per year, resulting in a payback of less than five (5) years.

The chiller installation was phased to maintain cooling capacity throughout the duration of the project.

The installation of an Ice Chiller Plant provided significant benefits including energy efficiency, reliability, and cost savings:

- Energy Efficiency: The Ice Chiller Plant is designed to operate efficiently, resulting in reduced energy consumption. By utilizing the ice chiller plant at night and during off peak periods, when energy costs are lower, the cooling process is optimized and energy operational costs and demand charges are reduced.

- System Reliability: The Ice Chiller Plant enhances the reliability of the cooling system. Ice storage allows for better load management, ensuring consistent performance even during peak demand periods. The stored ice is used during the day to offset the need and demand of the heat reduction/chiller plant system

- Cost Savings: The project has achieved substantial cost savings. By shifting energy usage to off-peak hours, the facility has realized annual savings of $1 million in utility demand charges and consumption costs. Additionally, the payback period for this investment is less than 5 years.

The Ice Chiller Plant Installation demonstrates how innovative solutions can improve efficiency, reliability, and beneficial financial outcomes for mission-critical facilities.