PREFABRICATED CONTAINERIZED MODULAR DATA CENTER - Denver, CO

Client: Confidential Financial Services Client

Summary: SIGMA7’s prefabricated containerized modular solution transforms a conventional data center into a modern, modular, and efficient facility.

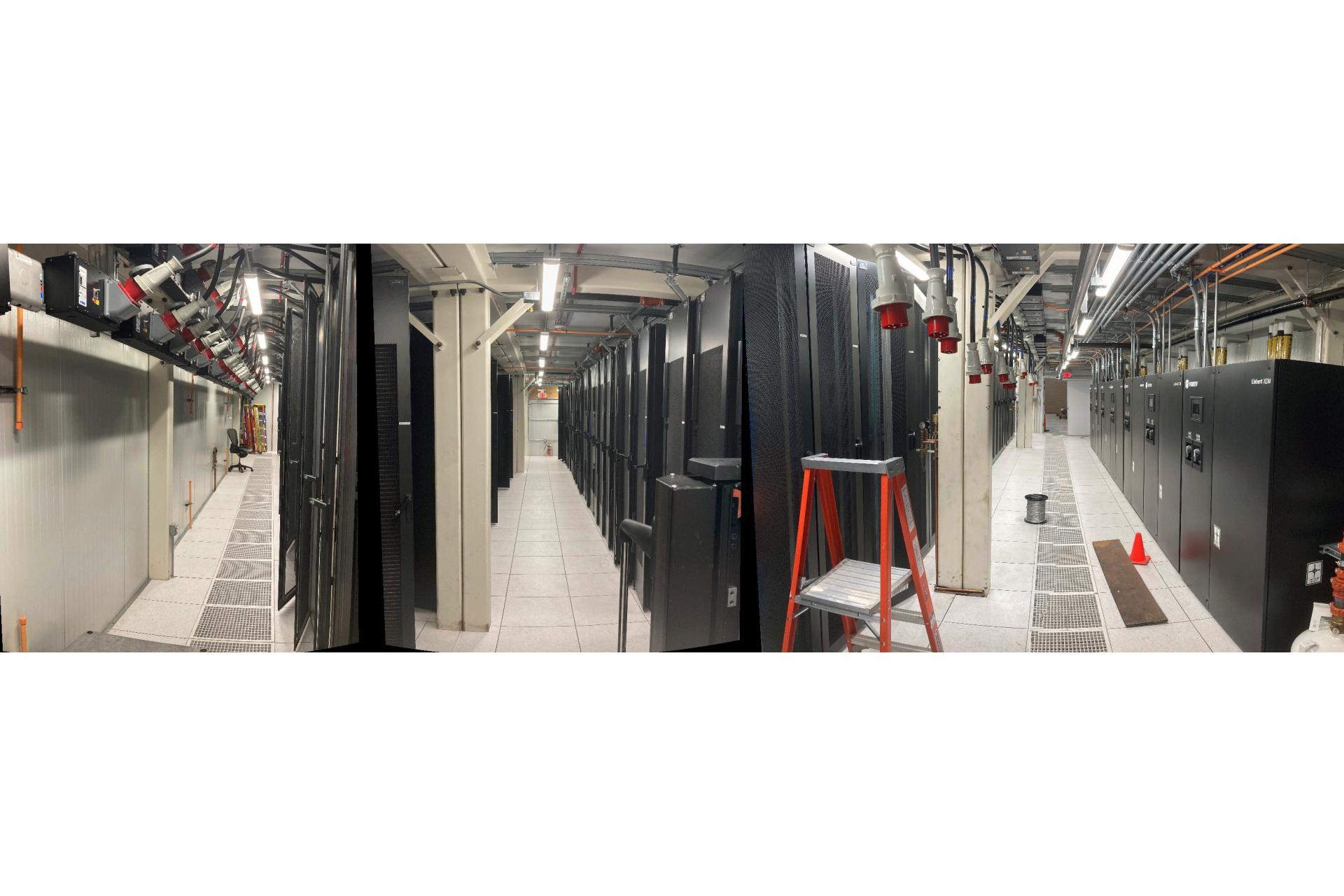

SIGMA7 developed, designed, and delivered a custom prefabricated modular data center solution, working hand-in-hand with our client and along with the enclosure and component manufacturers. The modules included separate power and production enclosures to replace a portion of their existing 'traditional' enterprise data center scheduled for refresh.

The enclosures were rigged into an existing structure, a former data center hall, modified and prepared to accept the modular components. The solution also leveraged the existing switchgear and generator plant, both modified to accommodate the modules.

The solution was developed based upon 2N redundancy. The design solution utilizes a pair of single wide containerized 'power' modules that houses the 500kW UPS modules, Lithium-Ion batteries (LIB), Power Distribution Units (PDUs), cooling, and the fire suppression system. The production module, a triple wide container, included production cabinets, CRAHs, electrical distribution, and the fire suppression system.

Each production module is capable of supporting up to 48 cabinets averaging 20kW with a total useable module UPS capacity of 1,000kW.

Cooling is provided by DX (air cooled) systems mounted at grade and on the roof of the structure. DX cooling was select as it eliminates the need for cooling/make-up water and related waste, which is good for the environment. The air-cooled system was designed to take advantage of free cooling within the semi-arid, high desert climate in which the site is located.

The modular concept was a strategic benefit. The equipment was assembled off-site in parallel with the construction and modification of the existing structure resulting in a reduction of the schedule duration and cost of the project. The factory pre-fabrication under controlled conditions assured consistent quality, precision air flow provides for higher rack loads, the ‘plug-and-play’ containers are energy and space efficient resulting in a higher PUE contributing to lower operating cost and total cost of ownership.

This initial installation consisted of two (2) 1,000kW power modules, each containing two (2) 500kW UPS modules, and a production module. Additional modules are planned for future phased implementation.

Prefabricated modular data centers offer several advantages over traditional data center construction, including:

- Scalability: Prefabricated modular solutions allow data center operators to add capacity faster than traditional approaches. This speed-of-deployment is crucial to keep up with the growing demand for data center capacity. Whether you’re expanding, upgrading, or building a new facility, Prefabricated containerized modular data center solutions compress timelines and help to achieve expansion goals faster and more efficiently. By eliminating tasks like sourcing system components and coordinating delivery, these solutions streamline the process.

- Efficiency: Prefabrication enables streamlined processes performed in a controlled environment by specialists. Unlike the traditional “stick-build” process, where distinct phases involve different contractors and vendors, prefab data centers are managed by a single partner. This consolidation can significantly shorten the timeline for bringing a new facility online. Additionally, prefabricated components are engineered for minimal waste, both in terms of materials and energy. They can also be factory witness tested, expediting the start-up and commissioning process.

- Portability: Containerized data centers are modular and can be shipped to a site pre-assembled. This flexibility allows for faster deployment compared to traditional white space construction. They are designed to be portable, making them suitable for various scenarios.

- Cost-Effectiveness: Prefabricated solutions often result in lower costs due to reduced construction time, efficient processes, and minimized waste.